- Trucks

- e-Mobility

- Services

- Dealer network

- Stories

Power-to-Liquid

Up to 100% reduction in CO₂ emissions

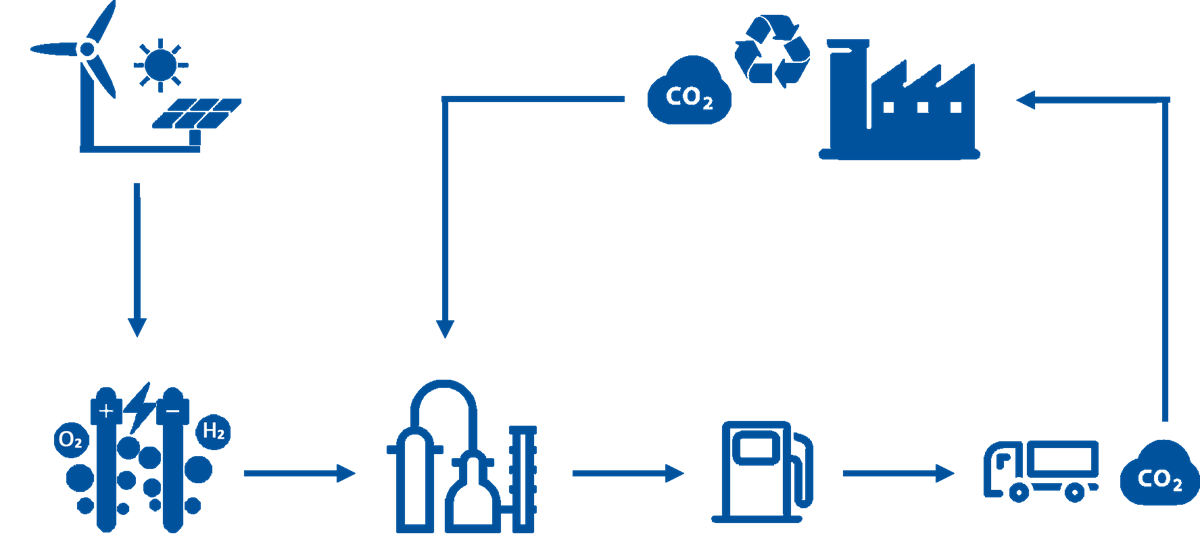

Looking into the further future, there are fuels on the horizon that are 100% CO2 neutral from production to combustion and that are perfectly suitable to power the internal combustion engine. An example are the so-called renewable ‘Power-to-Liquid fuels’ or so-called e-fuels, whereby hydrogen is generated via electrolysis, using green electricity captured from wind and solar energy.

Collecting the CO2

This hydrogen is combined with recycled CO2 to produce a synthetic fuel. Filters that are being developed to capture and store CO2 are central to the principle of ‘Power-to-Liquid’ fuels. Collecting the CO2 released during combustion and combining it with hydrogen completes the cycle. In fact, CO2 that leaves the exhaust is used to create new fuel.

CO2-neutral

The future ‘Power-to-Liquid’ fuels can be distributed via existing fuel distribution networks and could already be used in the modern combustion engine. Using these fuels is completely CO2 neutral, provided that the hydrogen is produced using for instance solar, water or wind energy. ‘Power-to-Liquid’ fuels are currently being produced on a small scale and at high prices. It is expected that these fuels will become more widely available between 2025 and 2030.

To create e-fuels, hydrogen is generated via electrolysis, using green electricity captured from wind and solar energy. This hydrogen is combined with recycled CO2 to produce a synthetic fuel.